PLA

Raw Material and Production

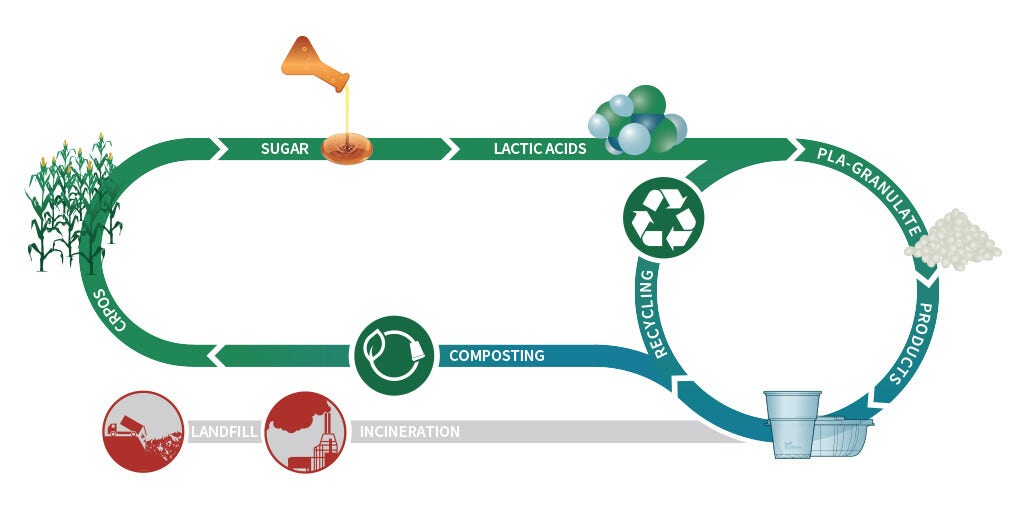

PLA stands for Poly Lactic Acid. The material PLA is usually made from fermented corn sugars or sugar beets, which are used to manufacture this type of biobased plastic. PLA plastics have similar features as traditional petroleum plastics (PS, PP, and PET), but they’re considerably more eco-friendly. For example, the production of PLA uses less energy and generates 65% less greenhouse gases than the production of conventional plastics.

PLA products are sensitive to heat and therefore only suitable for cold products. PLA products can be used with cold dishes and drinks of up to 40˚C. Our CPLA products are more heat-resistant. According to the EN-13432 composting standard, our PLA products are 100% biodegradable and compostable. In an industrial composting facility under optimum conditions (oxygen, moisture and heat), PLA will be fully composted within 8-12 weeks. Moreover, PLA is non-toxic and is made from a natural renewable resource.

PLA is used to produce clear cups, lids, salad boxes and coatings for our coffee cups and kraft menu food containers and cartons. PLA is made from the starches and sugars of corn and is completely biobased. The corn is milled and then the sugars are fermented into lactic acid. This lactic acid is then polymerized to create Poly Lactic Acid; PLA.

End of life

In the composting process, the material will decompose and all that remains is CO2, H2O (water) and biomass. The CO2 that is being released is exactly the amount the original plant material absorbs during growth. The compost can be used as a soil improver or an organic fertilizer. Another option is

anaerobic digestion, whereby biogas is created.