Corn

Raw Material and Production

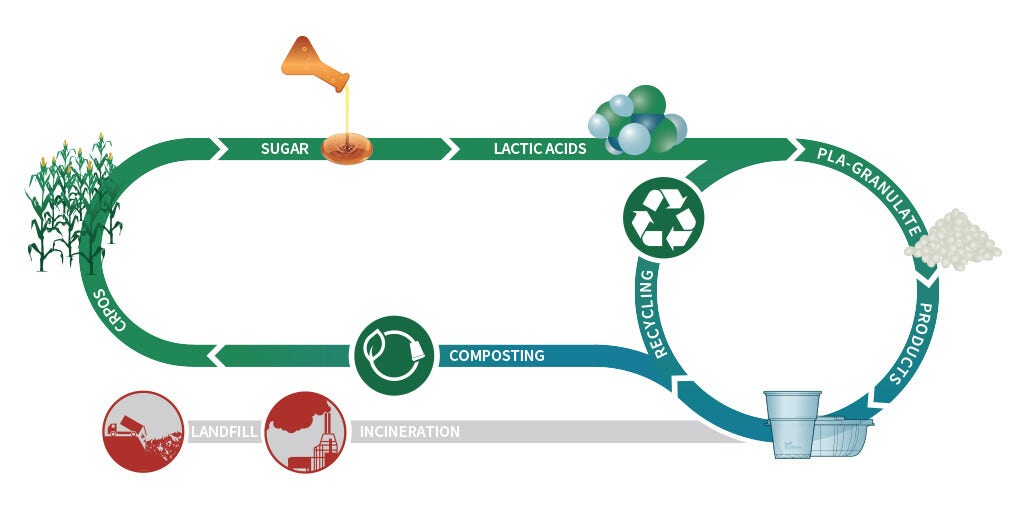

A lot of our products are made from a bioplastic named PLA. PLA is used to produce clear cups, lids, salad boxes and coatings for our coffee cups and kraft menu food containers and cartons. PLA is made from the starches and sugars of corn and is completely biobased. The corn is milled and then the sugars are fermented into lactic acid. This lactic acid is then polymerized to create Poly Lactic Acid; PLA. The PLA pellets are then sent to factories all over the world to be turned into sustainable disposables. PLA products are known for their rigidity, transparency, and being 100% industrially compostable and food safe. PLA is not heat-resistant and therefore can only be used for cold drinks and dishes of up to 40-45°C.

The production is also very sustainable because there is a 75% reduction in CO2 emission compared to regular oil plastic production. PLA is also certified compostable according to EN-13432 meaning that it degrades for at least 90% within 90 days in an industrial composting facility.

CPLA is also made from the sugars and starches of corn. But in the production process, talc is added so that the PLA crystallizes and Crystalized Poly Lactic Acid is created. CPLA consists of 70 to 80% PLA and 30 to 20% talc so that a heat-resistant (up to 85°C) and fully compostable bioplastic is created.

End of life

In the composting process, the material will decompose and all that remains is CO2, H2O (water) and biomass. The CO2 that is being released is exactly the amount the original plant material absorbs during growth. The compost can be used as a soil improver or an organic fertilizer. Another option is anaerobic digestion, whereby biogas is created.